Digitize, Standardize, and Accelerate Inspection & Maintenance Work Packs

The α-Phe Work Pack Module enables engineering and maintenance teams to create, review, execute, and close-out work packs digitally, streamlining the delivery of inspection and maintenance activities across your asset base.

Designed specifically for Asset Integrity and Reliability programs, this module links inspection scope, anomalies, and risk mitigation tasks into a structured, auditable workflow — ensuring consistency, traceability, and compliance.

What Is a Work Pack?

A Work Pack is a structured document or digital package that consolidates the scope of work, required tools, safety information, inspection methods, technical drawings, and reporting templates needed to carry out a specific integrity or maintenance task.

Traditionally created manually, work packs are often inconsistent, error-prone, and difficult to track. The α-Phe platform eliminates these issues by providing an integrated digital solution.

Why Use the α-Phe Work Pack Module?

- Faster turnaround from planning to field execution

- Standardized templates for inspection, thickness measurement, NDT, repair, or cleaning

- Links with RBI, Anomalies, and Inspection Plans

- Multi-discipline support (static equipment, piping, structure, etc.)

- Real-time updates between planner and inspector

- Field execution via tablet-friendly forms (online/offline)

- Automatic closure reporting and KPI tracking

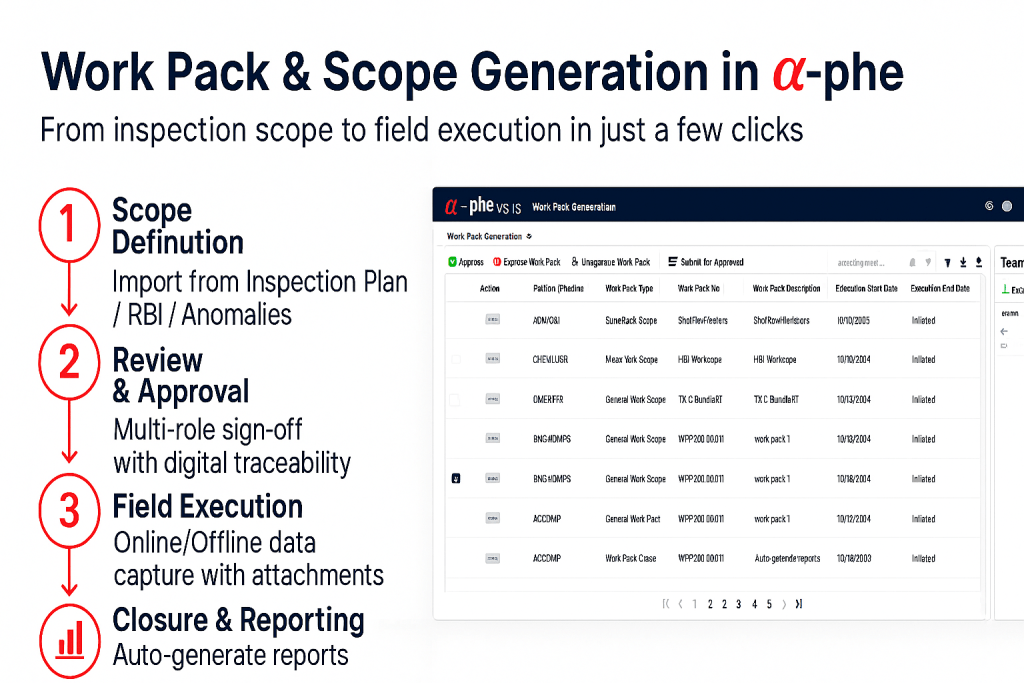

How the Module Works in α-Phe

1. Scope Identification

- Scope is generated from Inspection Plan, RBI Output, or Anomaly Management and other sources.

- Users select equipment and assign work type (e.g., NDT, Internal Inspection, Anomaly Repairs, Dead Leg Campaign etc…).

2. Work Pack Generation

- Templates are automatically populated with:

- Scope of work

- Task-specific instructions

- Hazards and controls

- Reference documents

- Reporting checklists

3. Review and Approval

- Work packs undergo multi-level review and digital sign-off via α-Phe’s workflow engine.

4. Field Execution

- Inspectors access work packs via web or tablet.

- Real-time status updates, attachments, and readings are captured directly into the system.

5. Closure and Reporting

- Completed packs auto-generate inspection reports.

- Findings are routed to Anomaly or Repair Register if required.

- KPIs such as TAT, overdue actions, and pack effectiveness are auto-tracked.

Integration with Other α-Phe Modules

| Integrated Module | How It Works Together |

|---|---|

| RBI / Risk Matrix | Defines and prioritizes inspection scope |

| Inspection Planning | Feeds scheduled tasks into work pack generator |

| Anomaly Management | Escalates findings from work packs to anomaly register |

| Repair Management | Converts findings into repair scopes and timelines |

| Digital Dashboard | Visual tracking of all open/closed work packs |

Field-Friendly, Audit-Ready

- Fully digital and PDF-exportable

- Field-level image uploads, and auto time-stamps

- Historical traceability of who created, approved, executed, and closed each pack

- Can be integrated with SAP, MAXIMO, or EAM systems for unified execution

Example Use Case

During a turnaround, the static equipment team uses α-Phe to generate 65 NDT work packs across pressure vessels and piping. All packs are digitally approved, downloaded to tablets, and executed offline. Readings are uploaded back into the system, with 12 anomalies automatically routed to the repair team, reducing close-out time by 40%.

Ready to Eliminate Manual Work Packs?

The α-Phe Work Pack Module transforms how integrity and maintenance activities are executed, from reactive, paper-based systems to a smart, connected digital environment.

Request For Free Demo / Quote

Schedule a 30 minute to 1hr call

In the 30-minute to 1hr call we will demonstrate the software and explain the concept around AIMS software, we will clarify all the queries you may have. The demo will be scheduled over Microsoft Teams. The link to connect will be provided after reviewing the submission of the request for free demo form below.